Insert Injection Molding, Overmolding Injection Molding

Insert molding is a molding process in which plastic is injected after a prepared different material, and the insert is loaded into the mold. Besides that, the fused plastic is perfectly joined and cured together with the insert. The insert molding process can be used for the production of integrated products.

Insert Molding: How to Ensure Consistent Outcomes

Dec 02, 2020 · The first step in insert molding is to custom-build a tool to accept a solid component or part as an insert. That insert is placed into the tool, and a thermoplastic elastomer (TPE) is injected into the tool cavity, coating the insert in a smooth layer of plastic. After cooling, the tool is opened and the part is removed and inspected.

Insert Molding and Encapsulation - Romeo RIM

Various types of inserts come with their own benefits and drawbacks, so contact Romeo RIM today for help deciding just which insert is right for your next project! 74000 Van Dyke Ave, Romeo, MI 48065. 586-336-5800 Mon-Fri, 8am until 5pm EST. sales@romeorim.com We reply within 48 hours. Tags: Insert Molding.

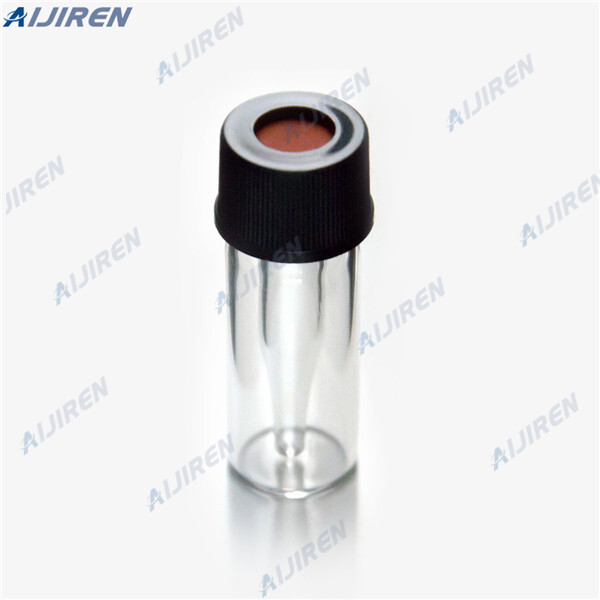

250ul insert for Aijiren from Aijiren-Aijiren HPLC Vials

Vial Insert, 250 uL, Glass, conical with Polymer feet, 100/pk. Aijiren Technologies Item Weight: 2.12 ounces Model Number: 77 Number of Items Vial insert, 250 uL, glass with polymer feet, 100/pk Insert size: 5.6 x 30 mm. Send Inquiry. Chat Now.

Injection Molding 101: Insert Molding - YouTube

For more, read our Injection Molding Guide: https://www.jayconsystems.com/tutorials/cat/tutorials/post/engineering-guidelines-to-designing-plastic-parts-for

250ul Micro Insert, Flat Bottom for 8-425 Vials

Clear Glass Micro Insert is used to ensure the most accurate and reliable analysis of your lab samples. 250ul Micro-Inserts, flat Bottom. Micro inserts, when used in conjunction with autosampler vials, allow for maximum sample recovery and easier sample removal. Micro Inserts Details

What Is Insert Molding, Metal insert molding services China

Apr 23, 2021 · What Is Insert Molding. Insert Molding metals and plastics together in a molded part, or multiple metals or materials molded together into a single molding part. we sometimes called metal insert molding or metal screw/ brass insert molding, sometimes we call insert molding as over-molding as well. Insert molding (moulding) can be used in

3 Types of Insert Molding and Encapsulation - Darter Plastics

Dec 13, 2019 · There are three main techniques for encapsulating an insert: Multi-component injection molding, also known as co-molding, involves injecting some combination of multiple plastics and metals into the mold at the same time. These materials then join together, resulting in a stiffer, stronger piece. Multi-shot injection molding is similar to multi

Insert Molding Solutions | Insert Molding Processes | Ferriot

Insert-Molding Process. The video here demonstrates an automated robotic process for a recent insert-molding project at Ferriot. Shown are both the picking and placement of the insert as well as the picking of the finished part. For this project, the insert was a metal hinge pin. It was molded with plastic to create a door for another piece of

Insert Injection Molding Process - Plastic Mold | Plastic

Jun 29, 2019 · In the simplest sense, insert molding is done on an injection molding where you mold plastic around an object that has been placed in a mold. The final product is determined by the shape of the mold and what is placed inside the mold. A good example of a part manufactured on an insert molding machine is a Sub D Connector.

Insert Molding Process Step by Step - RYD Tooling

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

Design and production guidelines for Insert Molding | Fast Radius

Generally speaking, the insert should extend a minimum of 0.016” (0.4 mm into the cavity of the mold), and, in order to prevent sink marks in the plastic, the molding beneath the insert should be a minimum of one-sixth the insert’s diameter. A good rule of thumb when designing inserts is to ensure that they stay small relative to the

Insert Molding - Lubrizol

High-Quality Insert Molding. LLS Health’s experienced team specializes in a variety of insert molding process techniques to deliver the highest-quality product possible. Our expertise includes: High bond strength. Experience with restricted, unrestricted and compounded materials. Numerous shapes and sizes. Extruded components to molded

Insert Molding Design Guide:How to Mold Inserts - rydtooling

The following is a quick review of these steps. Preparing the Machinery: Preparing the machinery used in the process is the first step when it comes to designing insert molding. One has to check the machine tolerances and the alignment of every part to ensure that the final product comes out clean. Inserts: The next step is deciding the type of

Insert Molding - Applications & Use Cases - Basilius Inc.

Insert molding is an injection molding process used to encapsulate a component in a plastic part. The process consists of two basic steps: First, the component is loaded into the mold before the molding process. Second, as molten plastic is injected into the mold, it takes the shape of the part and locks the component into the plastic.