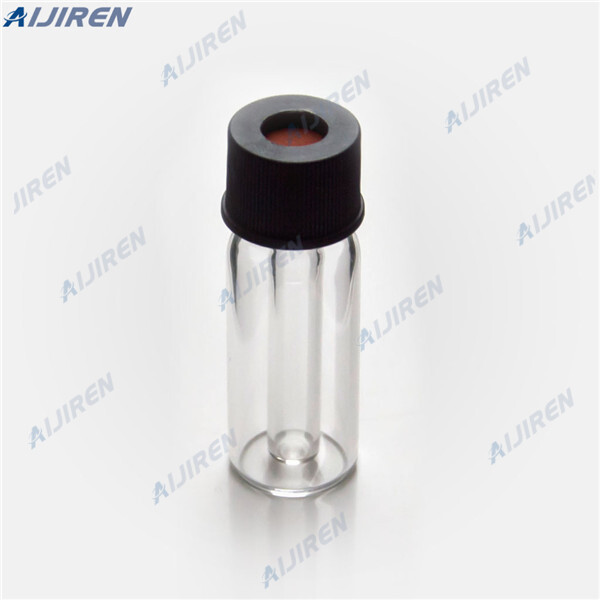

Sigma 250ul insert with mandrel interior and polymer feet for

Short Thread 9mm Clear Glass 1.5mL HPLC Autosampler Vials. 1 x 250uL Micro-Insert with Mandrel Interior and Polymer Feet, 29x5.7mm for 9mm vials, 100/pk, CV2044 + $16.38 1 x 250uL Micro-Insert, conical bottom, 31x6mm for 9mm vials, 100/pk, CV2046 + $10.96 1 x 300uL Micro-Insert, Flat Bottom, Clear, 31x6mm for 9mm vials, 100/pk, CV2050 + $6.19.

INSERT MOLDING | mddionline.com

Medical Polymers, Inc., Spencer, IN. Insert molding is an injection molding process whereby plastic is injected into a cavity and around an insert piece placed into the same cavity just prior to molding. The result is a single piece with the insert encapsulated by the plastic. The insert can be made of metal or another plastic.

Insert Molding | Threaded Inserts for Plastic Molding

A commonplace use of insert injection molding is creating plastic-covered metal cylinders to bolt pieces together and reduce stress on joined plastic parts. Threaded metal tubes or bracketed mounts minimize the amount of stress borne by the plastic piece. These simple compression limiters are ideally suited for insert injection molding since

What Is Insert Molding, Metal insert molding services China

Apr 23, 2021 · What Is Insert Molding. Insert Molding metals and plastics together in a molded part, or multiple metals or materials molded together into a single molding part. we sometimes called metal insert molding or metal screw/ brass insert molding, sometimes we call insert molding as over-molding as well. Insert molding (moulding) can be used in

Insert Molding for Parts & Components | AdvanTech Plastics

At AdvanTech Plastics, we often provide insert molded parts and products to the following: Automotive. We use the process to create rubber mounts and sunroof components for customers in the automotive industry. Electronics. We use the insert molding process to make a variety of electronic components, including relays, switches, and wire harnesses.

Insert Molding Design Guide:How to Mold Inserts - rydtooling

The following is a quick review of these steps. Preparing the Machinery: Preparing the machinery used in the process is the first step when it comes to designing insert molding. One has to check the machine tolerances and the alignment of every part to ensure that the final product comes out clean. Inserts: The next step is deciding the type of

Sigma 250ul micro insert vial exporter-HPLC Vial Inserts

High Recovery Vials and Inserts | Aijiren. hplc vial inserts for sale. Micro-Inserts--HPLC Vial Inserts. 250uL Micro-Insert with Mandrel Interior & Polymer Feet, 29*5.7mm, Suits for 9mm Vials 3. 10-425 Vilas Micro-Inserts Part No. I300 IV250-I(Economy) IV250 IP250-I(Economy) IP250 Description 300uL Micro-Insert, 31*6mm Clear, Flat Bottom, Suits for 10-425

Insert Molding: How to Ensure Consistent Outcomes

Dec 02, 2020 · The first step in insert molding is to custom-build a tool to accept a solid component or part as an insert. That insert is placed into the tool, and a thermoplastic elastomer (TPE) is injected into the tool cavity, coating the insert in a smooth layer of plastic. After cooling, the tool is opened and the part is removed and inspected.

Insert Injection Molding | Custom Manufactured Plastic Parts

Insert injection molding involves encapsulating a previously fabricated component in molten resin to produce a finished part. The inserted component is usually a simple object, such as a knife blade or surgical tube, but in some cases, inserts can be as complex as a battery or motor. Plastic insert molding is ideal for improving the strength

Overmolding & Insert Molding | Design Guidelines - Protolabs

101mm from parting line. Up to 203.2mm if the parting line can pass through the middle of the part. PROJECTED MOLD AREA. 1 3 sq. mm (plastic) 30968 sq. mm (silicone rubber) Height may be limited if using a silicone as the overmold material, and deeper parts are limited to a smaller outline. Minimum part volume is 0.025 cu. in. (40.98 cu. mm).

Overmolding vs Insert Molding: Denifition, Similarities, and

Jan 18, 2022 · Overmolding involves a two-step manufacturing process. The molding and curing of substrate entail one step, while the second step is molding another layer on the former. Insert injection molding does not involve a two-step manufacturing process. Still, it eventually leads to molding another layer on top of a product.

Insert Molding vs Overmolding Differences | Xometry

Insert molding is a subset of injection molding techniques similar to overmolding where metal components are placed into a mold cavity before the actual plastic injection. The insert is precisely positioned inside the mold either manually or by a robotic arm. The mold then closes, and plastic is molded over the insert, creating a single part.

Insert Injection Molding, Overmolding Injection Molding

Insert molding is a molding process in which plastic is injected after a prepared different material, and the insert is loaded into the mold. Besides that,the fused plastic is perfectly joined and cured together with the insert. The insert molding process can be used for the production of integrated products.

Laboratory analytical 250ul spring bottom vial insert for vials

Athena Vial Micro-Insert, Size: 250ul, Rs 800 /pack Athena. Vial Inserts Micro-Insert 0.3mL Amber Screw Vial Integrated w/Micro-Insert, w/Write-on Spot,Base Bonded, 11.6*32mm 1)9mm screw vials can be used on all common autosampler. 2)Standard narrow neck design for GC and HPLC. 3)9mm wider opening for easy puncture. 4)Clear, type 1 class A

250ul Micro Insert, Flat Bottom for 8-425 Vials

Clear Glass Micro Insert is used to ensure the most accurate and reliable analysis of your lab samples. 250ul Micro-Inserts, flat Bottom. Micro inserts, when used in conjunction with autosampler vials, allow for maximum sample recovery and easier sample removal. Micro Inserts Details